Luxury yacht shipbuilding is a multidisciplinary universe that ranges from engineering to design, from mechanics to information technology. This sector of the naval industry lives in a continuous research so that functionality and aesthetics can merge into increasingly beautiful and performing yachts.

The Evolution of Marine Technology

The evolution of naval technology is the result of study and research of the propulsion system, of the structural and technological aspects and how to expand and optimize performance and services through materials and new technologies.

Following every mark of technological innovation and being able to draw on the most disparate sectors, luxury yachts move among all the best that technique, style, and aesthetics can offer.

New Engines and New Fuels

The ship’s heart is in its engine and for this reason, also historically, the most macroscopic technical evolution is found in the propelling medium and in its power supply. If history has seen the sequence wind-steam-fuel, today new propulsion systems and new fuels are under study and application. Everything is done in the name of greater eco-compatibility and “hybrid” is the recurring word even if declined in different ways.

For some companies the wind becomes the green component that leads the zero emissions project, for others the future is focusing on hydrogen and green methanol, for others still it’s in the diesel-electric hybrid powered by biodiesel or in biofuel supplied by renewable raw materials.

Hulls’ Optimization

The hull is the submerged part of a vessel placed under the waterline. In order to determine the hydrostatic thrust that that allow the vessel to float, the volume’s weight of the displaced water must be equal to the vessel’s weight. From its shape depend: the boat’s resistance to the motion, much of its stability and most of its nautical qualities.

Bearing clearly in mind this shipbuilding’s principle, it’s easy to understand that the hull’s optimization, through more evolved shapes and lighter materials, brings greater efficiency and less fuel.

The Materials

The naval technology’s evolution also passes through the materials since the needs of each boat require special attention to the materials’ choice of each component.

If the first and basic requirement for any boat that touches the water is corrosion resistance, today, in the construction of yachts and megayachts, the choice of materials for structures, on-board plants, oufittings and furnishings is a constant search for materials that are increasingly lighter and aesthetically beautiful, green and performing.

In addition to some timeless materials such as steel and aluminium, improved in the production process for abating emissions and microplastics, or laminated teak renewed in FSC (Forest Stewardship Council) certifications, we find the entry of refined polymers and polycarbonates, new sustainable materials or derived from biotechnology research.

Among the latter: natural fabrics and yarns produced 100% from recycled plastics, fiber obtained from bamboo or eucalyptus pulp, regenerated leather and their totally vegan alternatives obtained from plastic waste and agricultural by-products.

Among the many new materials there are also sintered stones, obtained through a process that accelerates the metamorphic mutations obtained in conditions of high pressure and high temperature.

These mineral materials differ from natural stones, granites, and ceramics for many characteristics: ultra-compact surface, large slabs, very high physical-mechanical properties and low maintenance, in addition to the incredible aesthetic qualities fused to a green soul.

Design and Detail’s Customization

With the prospect of boats always pushed to the maximum in terms of technique and performance, new technologies, unthinkable in the past, are allowing us to go even further in terms of customization.

Today increasingly advanced software in combination with 3D printing offer possibilities to get the maximum choice in furniture and details. The need to live aboard a yacht with the same comforts of home translates into custom-made-solutions that migrate from the world of home design (as for wallpapers, fabrics, plaques), home automation and engineering.

3D printing, thanks to specific CAD software for each material, is thus applied to many compounds: from plastics to metals up to natural fabrics.

In this way, design freedom is combined with speed, efficiency, and flexibility to put unique objects of versatile, innovative, and smart design on board yachts.

Sustainability and Environmental Impact

The environmental impact and the sustainability of the naval product and the entire process that leads to its realization is an increasingly current and felt topic, with all its internal contradictions.

At present, it is unthinkable and unattainable a totally green finished product, not because a lack of propulsion technologies capable of zero the carburetion’s polluting impact, for example, but because, from a circular economy’s perspective, even the entire work chain that makes any ship or part of it should be pollution free.

While this introduction to the question, as honest as uncomfortable, is quite clear, it’s equally evident the effort of many sectors to reduce as much as possible the polluting impact that gravitates around the shipbuilding sector.

It’s possible to build more sustainable luxury yachts thanks to engines with low environmental impact, as we have seen talking about the evolution of naval technology, or with the use of renewed and sustainable materials but also through new products, solutions, and strategies.

Among the most interesting we find:

- Radiation-blocking glasses

- Solutions and equipment to produce clean energy

- Environmentally friendly anchors

- Smart waste management

- Blue economy’s protocols

Special Glass.

One way to go towards sustainability is in glazing. Using glass capable of blocking very high percentages of infrared radiation (80%) and 99% of UV rays, to change colour according to light and not temperature and at the same time be able to generate photovoltaic energy on board.

In a complementary way, be able to use the energy produced by the sun’s refraction or cover needs at sea using solutions and equipment to produce additional renewable energy (for example, wind, photovoltaic, hydrogen, etc) is an alternative solution to produce clean energy on board.

In a complementary way, being able to use the energy produced by the sun refracting on them or use solutions and equipment to produce additional renewable energy (e.g. wind, photovoltaic, hydrogen, etc.). to meet the needs at sea is another solution to produce clean energy on board.

Environmentally Friendly Anchors.

The ecological anchors instead, are made of aluminium with a higher percentage of silicium in the composition to ensure flexibility, density, and greater resistance to mechanical stress. These mooring systems, designed to damage as little as possible the seabed and with different anchoring systems calibrated according to the type of backdrop, are among the most interesting sea friendly innovations.

The Waste Cycle.

Another crucial issue talking about eco-sustainability is waste management: when the boat is under construction, when it’s at sea and when it’s moored.

The so-called 5R Strategy (Reduction, Reuse, Recycling, Raising, Recovery), fundamental for the environmental impact, is also valid for the naval sector and not only for the macroscopic part concerning the scraps of hazardous waste from shipyards (as for acetone used during the processing of fiberglass) but for the entire chain of recovery and waste disposal on board until its management and storage at the docking. Among the various projects, the most interesting are the implementation of on-board wastewater filtration systems on one side and anti-pollution systems and filtering of discharges to the sea on the other.

The Blue Economy’s Progress.

Finally, working in a seemingly less direct way, but operating throughout the system as a whole, the blue economy protocols aim to neutralize the footprint of the marine industry. Their vision to preserve the oceans is select suppliers who work by providing products and solutions increasingly sustainable in compliance with specific factors and regulations.

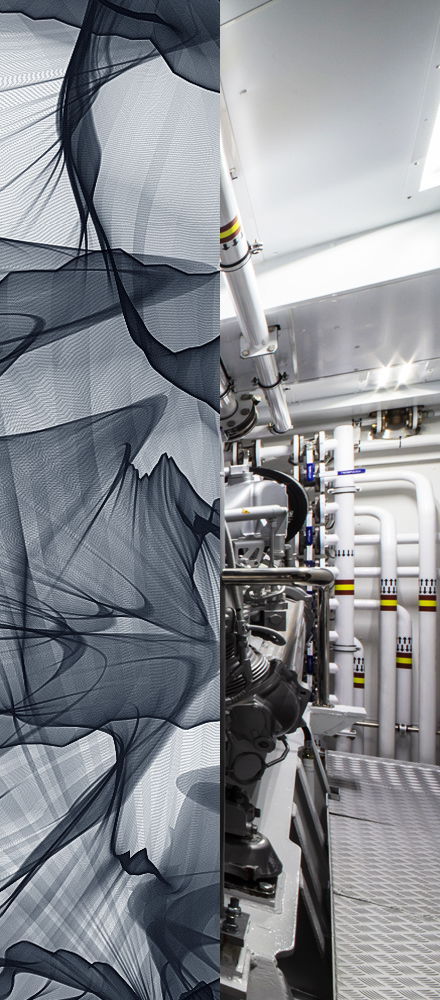

On board Automation and Safety

The exponential evolution of technology and the automation’s incoming into everyday life is now a proven reality. When it comes to the latest generation of yachts and megayachts, however, one is looking for much more than a home automation system to be applied to air conditioning, entertainment systems or curtains, lights, and windows control systems.

Safety.

Automation aboard luxury yachts, first and foremost, rhymes with safety: in fact, is fundamental allow a direct communication with engines, generators, and navigation instruments, as well as record, monitor and share data to enable the use of them to the crew on board and to the ground teams.

Minimizing manual operations, allowing accurate real-time optimization based on the performance detected on board the ship, improves safety on board and passenger experience.

Speaking of safety, another key technology is radar. Whether magnetron technology (i.e. transmitting radio frequency waves in short bursts and using high voltages) or solid-state (based on the Doppler effect) these instruments serve to avoid collisions in water. The more advanced ones filter out noise and interference caused by waves and navigation, can detect whether the targets are stationary or moving by monitoring potential collision situations, and allow objects’ shapes and distances to be displayed sharply on the display, make safer navigation both in normal conditions and in situations criticism.

The Future of Luxury Yacht Shipbuilding

What will affect the shipbuilding industry? Which emerging or currently developing technologies will determine how the yachts of the future will be built?

Today it’s not easy to understand what the construction of luxury yachts’ will be, because of the multiple productive and technological variables, but it is easy to imagine that design will play an increasingly influential and substantial role.

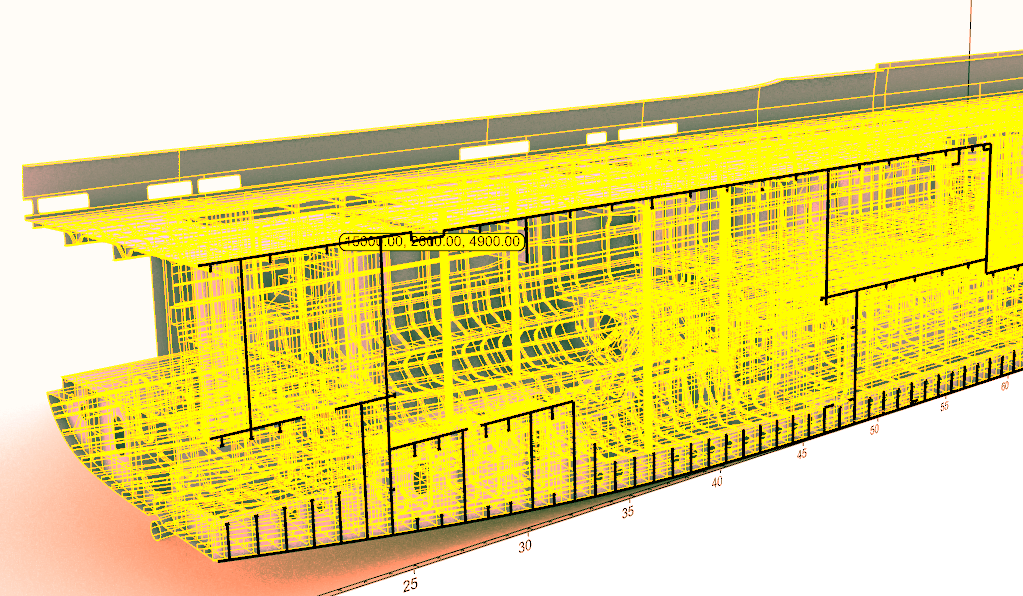

Designing with innovative technologies, for example, means being able to make a digital twin, thus allowing to analyze structures and systems, find potential unknowns and problems to estimate materials, weights, and fuel consumption.

The Future is in Design.

The future is in design and Kyma is the first to believe and invest in this idea.

The design steps, in Kyma, , involve creating an engineered model from an architectural 3D model and the general plans of the boat, structural calculations, structures’ 3D model made and developed with NAPA, FEM Analysis, scantling plan, study of technical room layouts and drafting of the functional diagrams of the plants, then moving on structures and plants executive design (nesting and piping) and completing everything with the drawings necessary for the preparation of the ship.

This leads to the creation of a boat’s digital twin, in which you can move around as if on board, evaluating accessibility, usability of the components, aesthetic impact and functionality of what has been designed. One can take measurements and query the various components, recalling directly from the 3D model, documentation or 2D drawings, having an interactive link to every document related to the project. This way of developing and organizing naval design serves to verify that everything that has been designed works, in a spiral of optimization that, starting in the various internal departments, extends to those who commissioned the project until those who will build it on shipyard.

Being able to verify what the design is creating, through the simulation of spaces and dimensions, passages, plants, and encumbrances is really valuable.

Being able to check all the reality on board and examine it to see if it corresponds to what was thought and check if it will encounter difficulties or blocking errors of any kind, allows you to leave the unreal world of calculations and drawings inside a computer and board the ship before even a single sheet of metal enters the shipyards.

Design: keyword and file rouge that combines 3D technology, artificial intelligence, virtual reality and augmented reality towards an increasingly functional, proactive and versatile construction.